![]() SAN FRANCISCO, CA, July 11, 2024 – Mantle, the leader in metal 3D printing technology for precision tooling, announced it has reached a significant milestone by securing $20 million in Series C funding. This achievement, raising the company’s total funding to more than $61.5 million, marks a crucial step towards widespread adoption of its precision metal manufacturing technology.

SAN FRANCISCO, CA, July 11, 2024 – Mantle, the leader in metal 3D printing technology for precision tooling, announced it has reached a significant milestone by securing $20 million in Series C funding. This achievement, raising the company’s total funding to more than $61.5 million, marks a crucial step towards widespread adoption of its precision metal manufacturing technology.

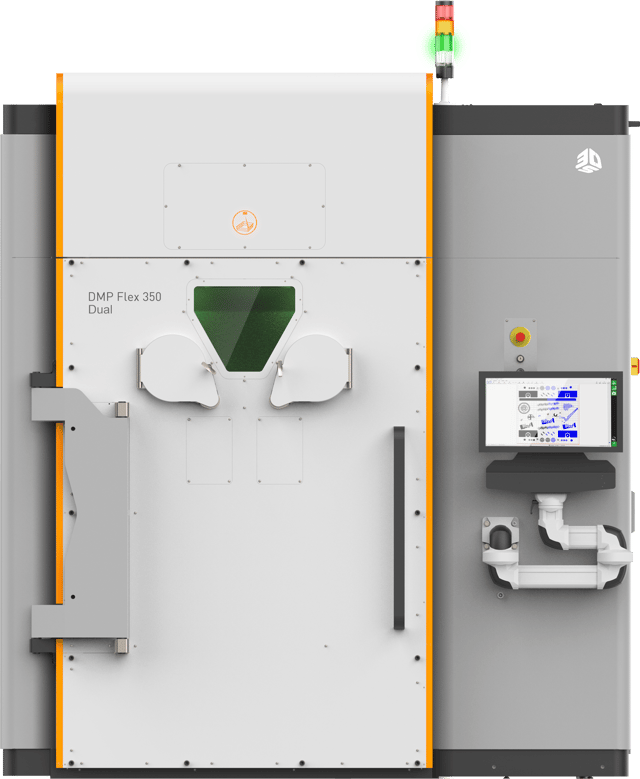

Mantle’s metal 3D printers are designed to deliver unparalleled efficiency, accuracy, surface finish, and tool steel properties, redefining the production of mold and die inserts. Tools made with Mantle’s technology have produced millions of parts, reducing both tooling lead times and costs. (Photo: Business Wire)

The Series C funding round will be critical in supporting Mantle’s rapid market expansion, scaling manufacturing to meet demand, and developing new capabilities and materials. Led by Schooner Capital, a Boston-based private investment firm, the round was also joined by the company’s largest existing investors, including Fine Structure Ventures, Foundation Capital, Corazon Capital, 11.2 Capital, and Build Collective.

“Mantle is poised to revolutionize the global tooling industry,” said Alexandra Manick, principal of Schooner Capital. “The company’s advanced manufacturing platform, TrueShape, is proven to deliver significant cost savings and, more importantly, unprecedented speed for its customers. This paradigm-shifting solution is readily adoptable and sorely needed to address persistent skilled labor shortages and accelerate product development timelines for industrial toolmakers and OEMs worldwide.”

Heyco Products, a US-based manufacturer of wire protection products and electrical components, has integrated Mantle technology into its advanced in-house molding and toolmaking capabilities. This move aims to reduce time-to-market for its products, enhance efficiency in its toolroom, and attract next-generation talent. The mold insert shown here was printed using Mantle’s metal 3D printing process to create a threaded cap. (Photo: Business Wire)

Reshoring Manufacturing with 3D Printing: A Path to Renewed Independence and Efficiency

The recent push towards reshoring manufacturing back to the United States has highlighted the urgent need for innovative solutions to address labor shortages while reducing costs and improving production efficiencies. Among the myriad of technologies attempting to step up to this challenge, metal 3D printing has emerged as a cornerstone, poised to redefine the future of American manufacturing.

“The fragile state of the global supply chain has triggered a massive reshoring initiative that sharply increased the demand for molded parts and thus toolmaking,” said Ted Sorom, CEO and co-founder of Mantle. “We’re navigating a twin set of hurdles: a toolmaking workforce in the US that has shrunk by half over the past quarter-century, coupled with the rising costs and extended lead times brought on by constrained toolmaking capacities. This has driven manufacturers to seek out groundbreaking solutions. For our innovative customers, the adoption of Mantle’s tooling technology has emerged as a key strategy to enhance labor productivity, cut expenses, and drastically shorten lead times.”

Easing Labor Scarcity of Toolmakers

Amid a severe labor shortage of toolmakers and skilled tradespeople plaguing the manufacturing industry—fueled by a workforce nearing retirement and a surging demand for the tooling essential for everyday products—manufacturers are turning towards automation and cutting-edge technology solutions to navigate these workforce obstacles.

Heyco Products, a US-based manufacturer of wire protection products and electrical components, deployed Mantle technology for its in-house molding and toolmaking capabilities.

“We purchased a Mantle system for two reasons: to reduce time-to-market for our products and to make our toolroom more efficient while attracting next-generation talent to Heyco,” commented Danny Anthony, Heyco’s vice president of operations. “By using Mantle to print mold tooling, we have already brought a new product to market two months faster than we would have otherwise. We also increased the throughput in our toolroom by giving our toolmakers access to the latest technology that makes them significantly more productive.”

General Pattern, a fourth-generation, woman-owned custom manufacturer specializing in low to medium plastic forming operations, has adopted Mantle’s advanced 3D printing technology to enhance the flexibility to build production tools at prototype lead-times and minimize the need to build entire tools by the toolmakers which significantly reduces costs, lead times, and labor. With Mantle’s technology, the company was able to produce a tool that not only saved 3.5 weeks of lead time but required just four active hours of toolmaker time.

“We pride ourselves in our commitment to staying at the forefront of technology. Tackling both the decline of next generation toolmakers and the relentless pace of industry demand, embracing Mantle’s metal 3D printing technology was not just a step towards innovation, it was a leap towards securing our legacy,” said Denny Reiland, third-generation CEO of General Pattern.

Positioned for Explosive Growth in Tooling Needs

After a year marked by double-digit growth in shipments, Mantle’s precision metal 3D printing technology is designed specifically to print injection mold tools, an application where other metal 3D printing methods have traditionally fallen short. This innovation slashes both the time and cost needed to fabricate high-quality molds and dies. The technology offers unmatched precision, surface finish, and metal properties while automating the tool production and reducing the dependence on scarce skilled labor.

Mantle’s innovative technology has played a crucial role in producing millions of end-use parts, ranging from medical devices and deodorant packaging to industrial components. By focusing on printing tools for mass production rather than the parts themselves, the company has tackled the longstanding issues of high costs and lengthy production times associated with tool creation for mass production. This strategic shift has resulted in cost reductions for customers exceeding 65 percent and accelerated manufacturers’ development cycles by up to 90 percent.

About Mantle

Mantle accelerates product development by simplifying how mold tool components are made. Mantle’s TrueShape metal 3D printing technology delivers the accuracy, surface finish, and tool steel properties required for demanding tooling applications. Tools made with Mantle’s technology have produced millions of parts while reducing tooling lead times and costs. Mantle is headquartered in San Francisco, CA.

To learn more, visit mantle3D.com.