![]() CAMBRIDGE, UK, Nov 16, 2016 – Granta Design and JAHM Software, Inc. announced an agreement to make JAHM’s extensive temperature-dependent materials property data available within Granta’s industry-leading materials software, GRANTA MI and CES Selector. The data includes over 2,800 materials (including metals, plastics, and ceramics) and 24,000 sets of temperature-dependent data for elastic modulus, thermal expansion, thermal conductivity, S-N fatigue curves, stress-strain curves, and more. This will give users of Granta software access to significantly more input data for simulation, along with an expanded library of high-temperature properties for use in materials selection.

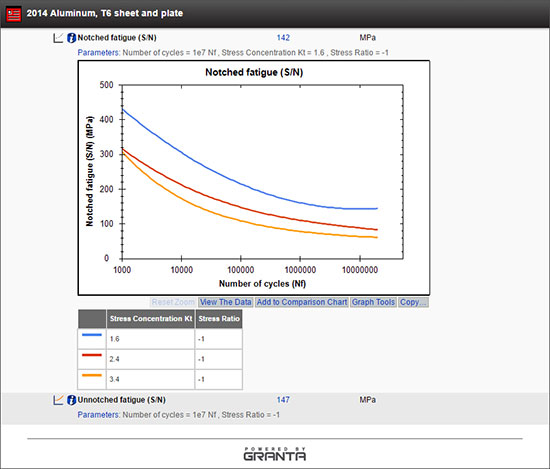

CAMBRIDGE, UK, Nov 16, 2016 – Granta Design and JAHM Software, Inc. announced an agreement to make JAHM’s extensive temperature-dependent materials property data available within Granta’s industry-leading materials software, GRANTA MI and CES Selector. The data includes over 2,800 materials (including metals, plastics, and ceramics) and 24,000 sets of temperature-dependent data for elastic modulus, thermal expansion, thermal conductivity, S-N fatigue curves, stress-strain curves, and more. This will give users of Granta software access to significantly more input data for simulation, along with an expanded library of high-temperature properties for use in materials selection.

Simulation is vital to product development but its accuracy depends on the quality of input data. Analysts can waste time finding the right material models and jeopardize the validity of their work if they use data that is not from a reliable, approved source. With GRANTA MI companies create a single, easily-accessible, traceable ‘gold source’ for all corporate materials data. They can manage the full lifecycle for simulation input data: from test, through analysis, to simulation model. This in-house data is complemented by an extensive library of leading reference data covering all material types. Adding the widely-used and respected JAHM data to this library further enhances its value for simulation. Analysts can access all of the data that they need in one place, including (via the GRANTA MI:Materials Gateway app) making it available and searchable from directly within CAE software such as Abaqus/CAE and ANSYS. This ensures accuracy and consistency, avoids error, protects investments in simulation, and increases confidence in simulation results.

For more information on the use of GRANTA MI to support simulation, join a webinar with General Motors and Jaguar Land Rover on December 7: How Major Manufacturers Find the Right Materials Data for Simulation.

The JAHM data will also be useful in materials selection studies, for example, when screening the ‘universe’ of available materials to focus in-depth design or simulation on the likeliest candidate materials. CES Selector is the standard tool for materials selection and graphical analysis of materials properties. Its powerful charting tools and systematic selection features filter material options based on their properties and help users to assess trade-offs. Adding the JAHM data will provide improved coverage of high-temperature properties and also enable engineers to identify material grades for which good simulation input data exists.

“We’re pleased to be working with JAHM to further extend Granta’s solutions for simulation and selection,” said Dr Patrick Coulter, chief operating officer at Granta Design. “The additional data reinforces Granta’s strategy to provide the best single source of materials data across the broad range of engineering applications.”

JAHM’s John Selverian added: “We are very excited to announce this partnership with Granta. Their advanced selection and search tools, coupled with our temperature-dependent properties database, means that finding the right material and simulation data for your designs is just a few clicks away, leaving more time for design evaluations and quicker decision making.”

About JAHM Software, Inc.

JAHM Software, Inc. was founded in 1998. It’s mission is to provide fast and easy access to temperature-dependent material property data. It is based in North Reading, MA, USA.

For further information go online to www.jahm.com.

About Granta Design

Founded in 1994 as a spin-out from the University of Cambridge, Granta helps hundreds of engineering enterprises to manage information on the materials (metals, plastics, composites, and more) that are essential to their businesses. They help to develop and apply material intelligence, making better materials decisions, saving time and money, and reducing risk as they optimize their products. They also provide supporting resources to thousands of university educators worldwide as they teach the next generation of engineers, scientists, and industrial designers about materials, processes, and sustainability.