Category Archives: Simulation

Convergent Science Releases CONVERGE 4

MADISON, WI, Apr 11, 2024 – Convergent Science recently released CONVERGE 4, a new major version of their CONVERGE CFD software. Version 4 includes several new solver options that increase simulation speed and accuracy, a host of new modeling capabilities, and a variety of new tools that expand the software’s functionality and improve user experience.

MADISON, WI, Apr 11, 2024 – Convergent Science recently released CONVERGE 4, a new major version of their CONVERGE CFD software. Version 4 includes several new solver options that increase simulation speed and accuracy, a host of new modeling capabilities, and a variety of new tools that expand the software’s functionality and improve user experience.

Centrifugal pump simulated with the new Under-Relaxation Steady (URS) solver available in CONVERGE 4.

CONVERGE 4 introduces a new steady-state solver that offers up to 100 times speedup for certain steady-state simulations compared to the previous solver. For cases with axisymmetric characteristics, a new 2D axisymmetric solver can provide improved spatial accuracy at a substantially reduced computational cost compared to a sector or full geometry approach. Version 4 also includes a new technique called cross-stream synchronization that can accelerate transient simulations in which the time-scales are very different for different regions of the domain, for example, in some conjugate heat transfer cases.

The modeling capabilities of CONVERGE have been significantly expanded in version 4. CONVERGE’s combustion models have been augmented to more effectively simulate alternative fuels such as hydrogen and ammonia and to more accurately capture spark ignition. The SAGE detailed chemistry solver can now be used to solve liquid-phase chemistry, applicable to problems including carbon sequestration and ocean acidification, and solid-phase chemistry, useful for modeling wildfires and battery reactions during thermal runaway.

For multi-phase simulations, CONVERGE 4 includes enhanced boiling and cavitation models as well as a new Multi-Fluid Multi-Field model that allows you to model multiple interspersed phases. These new models are beneficial for multi-phase applications in the marine sector and oil and gas industry, among others. In version 4, a variety of tools for wind and wave specification—crucial for conducting realistic offshore simulations—have also been integrated into the software.

CONVERGE 4 additionally contains a variety of new discrete phase models for phenomena including condensation and urea deposit growth in aftertreatment systems, along with the capability to model parcels in multiple reference frame simulations. The electric potential solver has been enhanced in version 4 to allow you to solve for a pair of coupled electric potential fields, which is valuable for battery simulations. Furthermore, CONVERGE 4 offers a thin-gap model for simulating lubrication systems and sealing with leakage, as well as new rotor models for efficiently simulating applications such as wind turbines and quadcopter drones.

In addition to the new modeling capabilities, a variety of pre- and post-processing enhancements have been incorporated into version 4. CONVERGE Studio, the graphical user interface for CONVERGE, now includes a customized version of ParaView as a built-in module. The ParaView module has been tailored for CONVERGE users’ needs, providing a seamless solution for data analysis and visualization. For pre-processing, users now have the option to create custom case setup panels, which display a user-defined subset of case setup inputs and parameters. Advanced users can generate these custom panels, which then offer a much simpler interface for end users who may not be CFD experts.

According to Keith Richards, co-owner and vice president of Convergent Science, “CONVERGE 4 offers an array of new capabilities that allow users to simulate a broader range of applications with greater accuracy and faster turnaround time. We’re excited for our customers to experience the benefits of this new version, which should enhance the user experience for clients across all market segments.”

Learn more about version 4 on the CONVERGE website.

About Convergent Science

Headquartered in Madison, WI, Convergent Science is a global leader in computational fluid dynamics (CFD) software. Their mission is to enable our customers to perform revolutionary CFD simulations by creating accurate, versatile, user-friendly software and providing unparalleled support.

Their flagship product, CONVERGE, is an innovative CFD software that eliminates the grid generation bottleneck through autonomous meshing and features a suite of advanced physical models, fully coupled detailed chemistry, and the ability to easily accommodate moving geometries. CONVERGE is revolutionizing the CFD industry and shifting the paradigm toward predictive CFD.

For more information about Convergent Science, please visit convergecfd.com.

Altair Wins 2024 Google Cloud’s Partner Award for DEI

TROY, MI, Apr 10, 2024 – Altair, a global leader in computational intelligence, announced that it has received the 2024 Google Cloud North America Partner of the Year Award for Diversity, Equity, and Inclusion (DEI). Altair is being recognized for its achievements in the Google Cloud ecosystem in its DEI initiatives, specifically for demonstrating a commitment to fostering diversity and inclusion, for addressing challenges related to attracting and retaining female and minority employees, and for continuously working to mitigate social and organizational biases.

TROY, MI, Apr 10, 2024 – Altair, a global leader in computational intelligence, announced that it has received the 2024 Google Cloud North America Partner of the Year Award for Diversity, Equity, and Inclusion (DEI). Altair is being recognized for its achievements in the Google Cloud ecosystem in its DEI initiatives, specifically for demonstrating a commitment to fostering diversity and inclusion, for addressing challenges related to attracting and retaining female and minority employees, and for continuously working to mitigate social and organizational biases.

“Google Cloud’s Partner Awards celebrate the transformative impact and value that partners have delivered for customers, through inclusion initiatives,” said Kevin Ichhpurani, corporate vice president, Global Ecosystem and Channels, Google Cloud. “We’re proud to announce Altair as a 2024 Google Cloud Partner Award winner and recognize their achievements as diversity enriches our teams and communities.”

“Altair is honored to win this prestigious award from Google Cloud – it’s a true testament to our tireless commitment to our people and to fostering an environment in which all employees feel welcomed, validated, and empowered,” said Gilma Saravia, chief people officer, Altair. “Garnering this award further demonstrates that Altair is a global leader, an organization where people always come first. We know that DEI work is never done – and we will always embrace the challenge to better ourselves year after year.”

Supporting its commitment to DEI initiatives and a positive work environment, Altair’s numbers speak for themselves. More than 75 languages are spoken and more than 50 nationalities are represented within Altair’s global workforce of over 3,000 employees. Women make up 43% of its executives and board of directors, both significantly higher than U.S. averages. And two standout employee-led resource groups – Women in Technology (WiT) and the Altair Black Employee Resource Network (ABERN) – further educate and empower all Altair employees by hosting more than 30 events each year focusing on personal growth, cultivating allyship, combating bias, and more.

To learn more about the award, visit https://cloud.google.com/awards/partners. To learn more about Altair, visit https://altair.com/.

About Altair

Altair is a global leader in computational intelligence that provides software and cloud solutions in simulation, high-performance computing (HPC), data analytics, and AI. Altair enables organizations across all industries to compete more effectively and drive smarter decisions in an increasingly connected world – all while creating a greener, more sustainable future.

To learn more, please visit www.altair.com.

Universal Robots Expands Partnership with MathWorks

![]() NATICK, MA, and ODENSE, Denmark, Apr 10, 2024 – Universal Robots, the Danish collaborative robot (cobot) company, has further strengthened its partnership with MathWorks, the leading developer of mathematical computing software, by joining the Mathworks Connections Program. The program supports organizations that develop and distribute complementary, commercially available products, training, and consulting based on MATLAB and Simulink. Last year, MathWorks became a UR+ partner within the Universal Robots ecosystem, consisting of more than 300+ approved developer companies creating products for the UR platform.

NATICK, MA, and ODENSE, Denmark, Apr 10, 2024 – Universal Robots, the Danish collaborative robot (cobot) company, has further strengthened its partnership with MathWorks, the leading developer of mathematical computing software, by joining the Mathworks Connections Program. The program supports organizations that develop and distribute complementary, commercially available products, training, and consulting based on MATLAB and Simulink. Last year, MathWorks became a UR+ partner within the Universal Robots ecosystem, consisting of more than 300+ approved developer companies creating products for the UR platform.

The two companies have already worked closely together, co-developing a support package for Robotics System Toolbox, launched in 2023. Engineers can design, simulate, test, and deploy their MATLAB-based cobot applications onto Universal Robots cobots using MATLAB and Robotics System Toolbox from MathWorks.

“In conjunction with MathWorks joining UR+, Universal Robots’ entry into the Connections Program formalizes the organizations’ commitment to helping engineers develop advanced cobot applications and ensures compatibility with new MathWorks releases,” said Jim Tung, MathWorks Fellow. With Universal Robots’ market leadership and the ability of MATLAB and Simulink to accelerate the pace of innovation, integrators and end users will continue to solve ever-more complex automation workflows.”

Jesper Kildegaard Poulsen, senior director of digital ecosystems at Universal Robots, said, “We are delighted to be a part of the Connections Program and to expand our collaboration with MathWorks. At Universal Robots, we constantly push the boundaries of what can be automated and how easily it can be done. Together with MathWorks, we look forward to continuing our common quest to simplify advanced cobot deployments for robotics engineers.”

Join MathWorks and Universal Robots at RoboCup 2024

As another testament to the two organizations’ close relationship, Universal Robots partnered with MathWorks to organize the Autonomous Robot Manipulation Challenge this July in Eindhoven, Netherlands, as an affiliated event to RoboCup 2024. The ARM Challenge is an educational, scientific competition that asks young researchers and students to address problems related to autonomous robot manipulation, organized by RoboCup and MathWorks since 2021. As a co-organizer in 2024, Universal Robots will provide its UR5e robots to be used by participants for the final rounds of the competition.

Read more about the ARM Challenge here.

For information on the integrated offering from MathWorks and Universal Robots, visit Universal Robots’ Connections Page.

About Universal Robots

Universal Robots is a leading provider of collaborative robots (cobots) used across a wide range of industries and in education. Founded in 2005 and headquartered in Odense, Denmark, Universal Robots aims to create a world where people work with robots, not like robots. Its mission is simple: Automation for anyone. Anywhere.

Since introducing the world’s first commercially viable cobot in 2008, Universal Robots has developed a product portfolio reflecting a range of reaches and payloads and has sold over 75,000 cobots worldwide. An extensive ecosystem has grown around the company’s cobot technology creating innovation, choice for customers and a wide range of components, kits and solutions to suit every application.

For more information, please visit universal-robots.com.

About MathWorks

MathWorks is the leading developer of mathematical computing software. MATLAB, the language of engineers and scientists, is a programming environment for algorithm development, data analysis, visualization, and numeric computation. Simulink is a block diagram environment for simulation and Model-Based Design of multidomain and embedded engineering systems. Engineers and scientists worldwide rely on these products to accelerate the pace of discovery, innovation, and development in automotive, aerospace, communications, electronics, industrial automation, and other industries. MATLAB and Simulink are fundamental teaching and research tools in the world’s top universities and learning institutions. Founded in 1984, MathWorks employs more than 6,000 people in 34 offices around the world, with headquarters in Natick, MA, USA.

For additional information, visit mathworks.com.

Ansys Joins BAE Systems’ Mission Advantage Program

to Advance Digital Engineering Across US Department of Defense

PITTSBURGH, PA, Apr 10, 2024 – Ansys announced it is working with BAE Systems, Inc., to accelerate the adoption of digital engineering and MBSE across the Department of Defense (DoD). Aligned with recent DoD guideline 5000.97, Ansys will help BAE Systems customers move away from manual processes and toward modernizing system design, delivery, and operation through an MBSE approach.

PITTSBURGH, PA, Apr 10, 2024 – Ansys announced it is working with BAE Systems, Inc., to accelerate the adoption of digital engineering and MBSE across the Department of Defense (DoD). Aligned with recent DoD guideline 5000.97, Ansys will help BAE Systems customers move away from manual processes and toward modernizing system design, delivery, and operation through an MBSE approach.

Ansys simulates the entire system-of-systems in action, at any location and at any time, to gain a clear understanding of its behavior and mission performance

BAE Systems delivers a comprehensive range of products and services for defense, intelligence, and civilian systems, including electronic systems, security solutions, and more. The company is working with Ansys to build efficient simulation processes and data management for system development, testing, evaluation, and sustainment of DoD programs through its Mission Advantage technology partnership program. Ansys will provide strategic bid support, architecture engineering, and go-to-market acceleration for sensitive digital engineering applications.

The Ansys strategic partnership will play a central role in the analysis, testing, and development of next-generation digital engineering environments to rapidly assess interoperability and new technology capabilities in the important areas of: AI and autonomy, integrated network system-of-systems, human-machine interfaces, and integrated sensing.

“Together, we are a force multiplier to bring digital mission engineering to the DoD,” said Daniel Perkins, director of strategy and technology partnerships for BAE Systems’ Intelligence & Security sector. “BAE Systems recognizes Ansys as the leader in simulation and we are excited to grow this strategic partnership.”

“Ansys solutions play a pivotal role for defense communities to act swiftly on high priority programs,” said Walt Hearn, senior vice president of worldwide sales and customer excellence at Ansys. “A robust digital engineering ecosystem is essential for maintaining a competitive edge. By joining the Mission Advantage program, Ansys solidifies its commitment to the advancement of digital engineering across diverse industries and supporting the next generation of innovation.”

About Ansys

When visionary companies need to know how their world-changing ideas will perform, they close the gap between design and reality with Ansys simulation. For more than 50 years, Ansys software has enabled innovators across industries to push boundaries by using the predictive power of simulation. From sustainable transportation to advanced semiconductors, from satellite systems to life-saving medical devices, the next great leaps in human advancement will be powered by Ansys.

For more information, visit www.ansys.com.

SimScale Announces AI-Powered Automotive Design Features

![]() MUNICH, Germany, Apr 10, 2024 – SimScale GmbH announced newly released AI-powered real-time automotive design features.

MUNICH, Germany, Apr 10, 2024 – SimScale GmbH announced newly released AI-powered real-time automotive design features.

Automotive design simulation of aerodynamics in the SimScale cloud-native simulation platform. (Photo: Business Wire)

SimScale, a fully cloud-native simulation platform, works with leading manufacturers, suppliers, and OEMs to ship better products faster while reducing R&D costs and increasing engineering innovation in a globally competitive landscape.

Automotive companies use SimScale to design and optimize their products using a broad spectrum of analysis capabilities, including mechanical, thermal, CFD, and electromagnetics. New features have now unlocked next-generation engineering techniques made possible with cloud-native simulation in which model and simulation data persists in a way immediately accessible for AI, generative design, and optimization workflows. This includes a fully capable AI simulation feature that sits side by side with its physics solvers and foresees all data from the simulation to be used for AI training and inference to accelerate rapid design convergence in the cloud.

The new features will be launched at the World Congress Experience (WCX) in Detroit, Michigan, USA, from April 16-18. SimScale will be exhibiting at Booth 454.

About SimScale

SimScale is the world’s first fully cloud-native SaaS application for simulation. By providing instant access to computational fluid dynamics (CFD), finite element analysis (FEA), thermodynamics, and electromagnetics analysis to over 500,000 users, SimScale has moved high-fidelity physics simulation technology from a complex and cost-prohibitive desktop application to a user-friendly cloud application accessible via a subscription-based pricing model.

For more information, visit website.

Altair Names Soothsayer Analytics Regional System Integrator

TROY, MI, Apr 9, 2024 – Altair, a global leader in computational intelligence, announced that Soothsayer Analytics has joined its regional system integrator (SI) network. Soothsayer will offer Altair’s comprehensive suite of data analytics and AI solutions, including Altair RapidMiner and Altair SLC, to its customers. The partnership will provide organizations in the US and Gulf Cooperation Council (GCC) region with advanced data analytics and AI technologies and drive innovation in the rapidly evolving technology landscape.

TROY, MI, Apr 9, 2024 – Altair, a global leader in computational intelligence, announced that Soothsayer Analytics has joined its regional system integrator (SI) network. Soothsayer will offer Altair’s comprehensive suite of data analytics and AI solutions, including Altair RapidMiner and Altair SLC, to its customers. The partnership will provide organizations in the US and Gulf Cooperation Council (GCC) region with advanced data analytics and AI technologies and drive innovation in the rapidly evolving technology landscape.

“As Altair continues to grow its data analytics and AI presence, establishing partnerships with leading consulting and technology providers is crucial. Partnering with Soothsayer allows us to empower organizations in the US and GCC with innovative AI solutions,” said Piush Patel, senior vice president of strategic relationships, Altair. “Together, Altair and Soothsayer will give customers unparalleled access to the latest advancements in data analytics and AI.”

“This collaboration opens new avenues for our customers to harness the power of advanced analytics and AI in unique ways. Altair’s technological prowess – exemplified in the Altair RapidMiner platform – aligns perfectly with our mission of delivering innovative, data-driven solutions,” said Gaurav Agrawal, chief executive officer, Soothsayer Analytics. “We look forward to this journey where our combined expertise will both solve complex challenges and create new opportunities for our clients in the evolving landscape of AI and data analytics. This partnership is poised to deliver advanced solutions that accelerate enterprise decision-making and optimize business outcomes.”

Founded in 2014 and headquartered in Livonia, Michigan, Soothsayer Analytics is a data science consulting firm specializing in the design, development, and deployment of end-to-end machine learning solutions. The company has offices in the US, Middle East, and India.

Altair works with a global network of channel and technology partners. To learn more or to become a partner, visit: https://www.altair.com/partners/.

About Altair

Altair is a global leader in computational intelligence that provides software and cloud solutions in simulation, high-performance computing (HPC), data analytics, and AI. Altair enables organizations across all industries to compete more effectively and drive smarter decisions in an increasingly connected world – all while creating a greener, more sustainable future.

To learn more, please visit www.altair.com.

Hose of South Texas Joins Tipco Technologies

The Exploration Company Selects Ansys

PITTSBURGH, PA, Apr 5, 2024 – Space logistics startup The Exploration Company is advancing sustainable space exploration by leveraging Ansys simulation solutions to develop its modular and reusable space vehicle, Nyx. With a revolutionary methane-based propulsion system, Nyx will begin by flying to stations in Earth’s orbit to deliver technologies for advanced research in areas such as microgravity, which has applications in the pharmaceutical and agricultural industries, among others.

PITTSBURGH, PA, Apr 5, 2024 – Space logistics startup The Exploration Company is advancing sustainable space exploration by leveraging Ansys simulation solutions to develop its modular and reusable space vehicle, Nyx. With a revolutionary methane-based propulsion system, Nyx will begin by flying to stations in Earth’s orbit to deliver technologies for advanced research in areas such as microgravity, which has applications in the pharmaceutical and agricultural industries, among others.

Spacecraft propulsion systems are designed to withstand extreme loads and high thermal and pressure variables, without adding significant weight to the vehicle’s overall mass. Conventional turbo engines are heavy and rely on fossil fuels, posing sustainability challenges and range limitations as the space industry intensifies launch activity and deeper space exploration. Methane propulsion systems offer a potential solution — emitting fewer pollutants, extending travel capabilities, and achieving more predictively accurate landings because they are more agile and easier to navigate.

Nyx is designed to carry cargo to and from the Moon and space stations, free fly around Earth, re-fuel in orbit, and re-enter Earth’s atmosphere before embarking on future missions. The building blocks of Nyx are openly available to a wide array of aerospace companies to support the transition from gas- to electric-powered travel — not only democratizing space exploration but improving its sustainability.

The Exploration Company leverages Ansys solutions to fine tune engine and body specifications and speed development time for the reusable orbital vehicle. The team uses Ansys Fluent and Ansys Mechanical to optimize the design of propellant pumps and the overall engine layout, supporting systems that meet technical requirements for performance and durability. Additionally, Thermal Desktop plays a crucial role in the thermal design of Nyx, while Ansys Granta helps source and manage material data, driving simulation accuracy, reducing material costs, and lowering project risk.

“Through the Ansys Startup Program, we can answer critical design questions in the early stages of our engines’ development,” said Sebastien Reichstadt, lead propulsion engineer at The Exploration Company. “Ansys’ proven high-fidelity simulation and interactive modeling allow us to quickly conduct iterative designs and prototyping up to validation. Only with Ansys simulation can we ensure that the propulsion systems of Nyx will meet the stringent requirements of spaceflight and reusability.”

“Efficient, eco-friendly propulsion is the next milestone in exploring the cosmos with greater precision,” said Walt Hearn, senior vice president of worldwide sales and customer excellence at Ansys. “In an industry that has many obstacles to physical prototyping, Ansys provides mission critical technology that empowers customers like The Exploration Company to strongly correlate simulation results with real-world data before ever going out into space. This results in a significant reduction in project costs and accelerates the timeline for unlocking the mysteries of deep space.”

About Ansys

When visionary companies need to know how their world-changing ideas will perform, they close the gap between design and reality with Ansys simulation. For more than 50 years, Ansys software has enabled innovators across industries to push boundaries by using the predictive power of simulation. From sustainable transportation to advanced semiconductors, from satellite systems to life-saving medical devices, the next great leaps in human advancement will be powered by Ansys.

For more information, visit www.ansys.com.

Concepts NREC Releases Agile Engineering Design System v2024.1

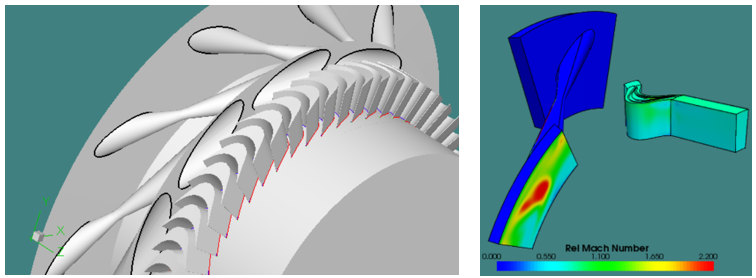

![]() WHITE RIVER JUNCTION, VT, Apr 5, 2024 – Concepts NREC is pleased to announce the latest release of the Agile Engineering Design System, an integrated suite of software modules for CAE and CAM specialized for turbomachinery.

WHITE RIVER JUNCTION, VT, Apr 5, 2024 – Concepts NREC is pleased to announce the latest release of the Agile Engineering Design System, an integrated suite of software modules for CAE and CAM specialized for turbomachinery.

The 2024.1 release of CAE software has improvements across the board for designing and optimizing all types of turbomachines – axial, radial, and mixed flow, pumps. compressors, and turbines. In particular, we focused this release on the design of turbopumps and have continued the job of teaching our software how our engineers predict the performance of a pump at the meanline level, reducing the needed iterations to go from specifications to CFD-ready geometry. The release of MAX-PAC continues their progress towards making MAX-PAC the only CAM software needed in a shop that machines impellers and blisks. They have made it easier to go from CAD to a MAX-PAC configuration and make collision-free toolpaths.

Dr. Peter Weitzman, president of software sales & business development said about v2024.1, “Our customers are the key to our success. Every time I am asked by a potential new user if our software has a needed capability the answer is almost always yes, and usually it’s because another customer pushed us to develop that capability in the past. This new version is available thanks to the feedback from thousands of users over decades of design and manufacturing experience.”

Version 2024.1 is available now for active Agile Product Support (APS) members to download at the customer support center or by emailing support@conceptsnrec.com.

About Concepts NREC

Headquartered in the USA, Concepts NREC is the only company in the world with end-to-end capabilities to take turbomachinery products from concept to reality. For more than 65 years, Concepts NREC has been at the forefront of turbomachinery design and innovation, providing engineering services, design software, CAM software, precision manufacturing, assembly, testing, training, and installation. Their mission is to provide the cutting-edge turbomachinery products, tools, and solutions the world needs for a sustainable future.

To learn more, visit www.conceptsnrec.com.

About the Agile Engineering Design System

The Agile Engineering Design System is a complementary suite of programs for CAE and CAM that covers the entire design process, from preliminary sizing through fluid dynamics and mechanical stress/vibration analysis. Final designs can be easily imported into their industry-leading CAM software, MAX-PAC, to create efficient 5-axis machining strategies.