![]() WILEN B. WOLLERAU, Switzerland, Oct 27, 2016 – AutoForm Engineering GmbH, the leading supplier of software solutions for the sheet metal forming industry, has announced the decision of Volkswagen’s tool shop to use AutoFormProcessDesignerforCATIA software for their process design. This strategic decision is based on the excellent results achieved during a successful joint project. By using AutoFormProcessDesignerforCATIA software, which includes a standard methodology for process design in the CATIA environment, daily work at Volkswagen’s tool shop can be carried out even more efficiently.

WILEN B. WOLLERAU, Switzerland, Oct 27, 2016 – AutoForm Engineering GmbH, the leading supplier of software solutions for the sheet metal forming industry, has announced the decision of Volkswagen’s tool shop to use AutoFormProcessDesignerforCATIA software for their process design. This strategic decision is based on the excellent results achieved during a successful joint project. By using AutoFormProcessDesignerforCATIA software, which includes a standard methodology for process design in the CATIA environment, daily work at Volkswagen’s tool shop can be carried out even more efficiently.

AutoForm-ProcessDesignerforCATIA was developed in collaboration with Volkswagen. The main goal of this project was to develop an advanced software product for process design that would enable users to rapidly create CAD quality die faces, which are required for CNC machining. The result of this joint project, AutoForm-ProcessDesignerforCATIA, is an excellent example of how distinguished technology leaders in their respective fields can successfully work together to develop an innovative product.

“Dedicated surfacing commands enable users to quickly create a process

design, including deep drawing and all secondary operations.”

In order to ensure that the new product covers the various requirements of different departments, the software went through an internal evaluation. The results achieved during several benchmark and comparative tests carried out with CATIA native and AutoForm-ProcessDesignerforCATIA were encouraging and motivating. A speed factor of up to five reached in these tests enables the user to rapidly create high quality surfaces while taking into account the initial die face design, its optimization as well as modifications made after changes to part design.

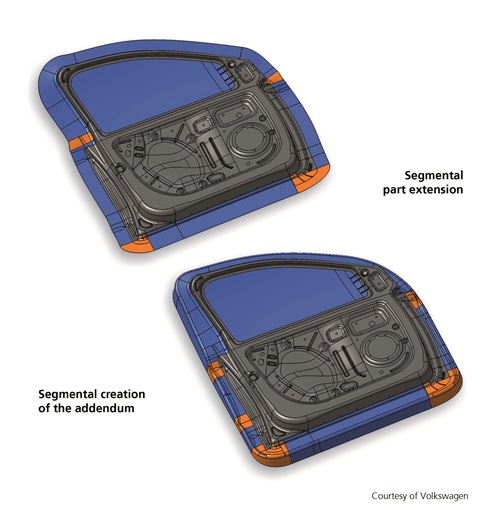

AutoForm-ProcessDesignerforCATIA combines AutoForm’s expertise in sheet metal forming process simulation with the powerful design functionalities of CATIA V5. Through dedicated surfacing commands, AutoForm-ProcessDesignerforCATIA enables the user to quickly create a die face layout, including deep drawing and all secondary operations in the CATIA environment. What is more, all generated surfaces fulfill class A surface requirements and can immediately be used for CNC machining. The software offers specially developed unique features, allows for the creation of draw shapes, supports company-wide standardization and implements a sophisticated methodology which reduces the complexity of process design. AutoForm-ProcessDesignerforCATIA is the result of an innovative, unique and quality-oriented approach in process design which improves daily work in process design departments.

About AutoForm Engineering GmbH

AutoForm offers software solutions for the die-making and sheet metal forming industries along the entire process chain. With 300 employees dedicated to this field, AutoForm is recognized as the leading provider of software for product manufacturability, tool and material cost calculation, die face design and virtual process optimization. All of the Top 20 automotive OEMs and most of their suppliers have selected AutoForm as their software of choice. Besides its headquarters in Switzerland, AutoForm has offices in Germany, The Netherlands, France, Spain, Italy, USA, Mexico, Brazil, India, China, Japan and Korea. AutoForm is also present through its agents in more than 15 other countries.

For detailed information please visit www.autoform.com.