ModuleWorks announces the 2024.04 release of its software components for digital manufacturing. This latest release of the ModuleWorks SDK contains a range of new and enhanced features for efficient toolpath generation, ranging from improvements in 2-axis machining to multi-axis surface finishing and more.

ModuleWorks announces the 2024.04 release of its software components for digital manufacturing. This latest release of the ModuleWorks SDK contains a range of new and enhanced features for efficient toolpath generation, ranging from improvements in 2-axis machining to multi-axis surface finishing and more.

Rotary Machining Roughing

Leads for Roughing

In open regions, toolpaths often start directly at the stock with a plunge movement, which can damage the tool or reduce tool life.

To address this, ModuleWorks 2024.04 now supports lead-in and lead-out options for rotary machining roughing toolpaths. These additional motions ensure a smooth entry and exit of the tool into and out of the material. This is especially useful for open pockets, as well as rest machining operations. It generates smoother transitions and ensures optimum start points on open contours. Tool wear and the risk of tool damage are also reduced.

Geodesic Machining

Improved Corner Smoothing

In sharp corners, machining is typically slow as the tool has to decelerate significantly. This leads to longer machining times and poor surface quality.

The ModuleWorks 2024.04 release introduces a corner smoothing option for geodesic machining toolpaths. This option improves the surface quality and reduces machining time as the tool no longer needs to decelerate and accelerate abruptly.

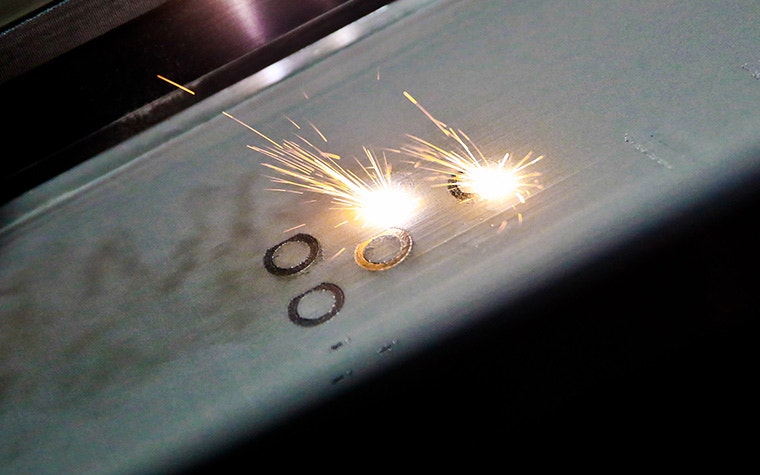

Deburring

Corner Arc Support for Chamfer Tools

In previous releases, cutting motions in the inner and outer corners were interrupted. A new enhancement in ModuleWorks 2024.04 now produces uninterrupted cutting motions.

The algorithm creates a continuous toolpath around the inner and outer corners when using a chamfer mill. With this improvement, intermediate links are no longer generated for 5-axis deburring operations. This reduces the linking motions and hence the overall cycle time for chamfering.

Existing Toolpath

Custom Rotate/Transform/Mirror Sequence

Previous limitations in tombstone machining meant that only one operation could be rotated with a fixed order of rotation before any transformation was allowed, and the mirroring operation was separate.

In ModuleWorks 2024.04, the Rotate/Transform/Mirror functionality has been enhanced and now includes a user-defined sequence option. Users can specify the order in which the operations are performed and set up a complex sequence of Rotate/Transform/Mirror steps via a tree structure. The machining direction for mirror operations can also be controlled in the tree. This makes it possible to machine multiple identical parts positioned in the machining area.

3-Axis

3D Contact Point Boundary for Finishing

Current containment options limit the toolpath to the tooltip which can sometimes leave unmachined areas.

The new implementation of the 3D contact point boundary accurately limits the finishing toolpath to the 3D containment on the part. Users no longer need to recreate the containment or manually add offsets, which reduces the programming time. It also ensures that the surface is completely machined.

Hole Making

External Thread Milling

Machining external threads on hard materials is challenging.

The new external thread milling feature allows thread milling on external orientations. The feature is especially useful for machining threads on difficult-to-cut materials. Another advantage is that a single tool can be used for machining multiple thread diameters.

ModuleWorks 2024.04 is available for download from the ModuleWorks website.

About ModuleWorks

ModuleWorks is the software component provider for the digital manufacturing industry. With over 200 employees and 1500 person-years of software development, ModuleWorks’ expertise in toolpath creation and simulation is recognized throughout the industry and its software components are already optimizing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software around the world. From standard products to exclusive development projects, ModuleWorks helps companies to bring their vision of Industry 4.0 to life.

For more information, visit ModuleWorks website.